Modular Construction

WHAT IS MODULAR CONSTRUCTION ?

Modular architecture is an innovation of the 20th century, not only it provides flexibility but it also saves the cost of construction while being sustainable.

GREENER

The factory-controlled process generates less waste, creates less disruption on site and enables tighter construction.

FASTER

Modular building construction is carried out at the same time as site work, allowing projects to be completed in half the time of traditional construction. Elimination of weather-related delays, because 60-90% of construction is carried out inside a factory, reducing the risk of weather-related delays. Buildings are occupied sooner, resulting in a faster return on investment. Once assembled, they are virtually indistinguishable from their site-built equivalents.

SAFER CONSTRUCTION

The indoor construction environment reduces the risk of accidents and the resulting liability for workers. The use of INSULATED CONCRETE FORMS and REINFORCED CONCRETE OFFER THE ULTIMATE AND BEST RESISTANCE TO EARTH QUAKES AND HURICANES

UNLIMITED DESIGN POSSIBILITIES :

Modular units can be designed to blend in with the exterior aesthetics of any existing building, and once assembled are virtually indistinguishable from their counterparts. Prefab walls : assembling the excellence

What are prefab walls?

Prefab walls are factory assembled based on building plans, and enable a construction project to begin regardless of the weather. A prefab wall can be up to10’ (3 m) tall by 40’ (12.2 m) long. Once delivered to the construction site, the prefab walls are installed with a crane. Each prefab wall is ready to receive interior and exterior finishes as well as the floors and the roof, based on specifications. We can create your prefab walls with any of our ICF products.

Benefits:

In addition to all the usual benefits of building with ISOLEED ICFs, prefab walls also provide:

- Respect for schedules

- Superior quality

- Trained and qualified employees

- Fast

- Less loss

- Less handling

- Optimized installation

- Adequate tools

- Minimal time on the construction site

Prefab wall components

Your building plan is studied by our professional team to determine the specifications of each prefab wall to be assembled in our factory. Prefab walls can be composed of the following elements, according to specifications :

- ISOLEEED ICFs

- Horizontal and vertical rebar

- Corner guides for wall angle

- Edge connection for straight walls

- Interior corner guides for T-shape walls

- Openings

- False frame for doors and windows

- Lintels

- Service openings

- Optimized installation

- Adequate tools

- Minimal time on the construction site

- Preparation for interior finishes

- Furring

- Electrical channels

- Floor anchors

- Preparation for exterior finishes

- Waterproof membrane for foundation walls

- Other components based on the chosen siding (offset for masonry, furring, etc.)

- Roof anchors

Building with prefab walls

Building with ISOLEED walls is simple. This process is similar to building on the construction site except that the walls are assembled in our factory, without concern for the weather. Once ISOLEED prefab walls arrive at construction site, installing them is fast and the building structure will be up in no time.

1. DESIGN AND PLANNING

Based on building plans, workshop plans are made with all necessary specifications and procedures for factory assembly and construction site installation. All activities are managed by a team of professionals to ensure an irreproachable quality.

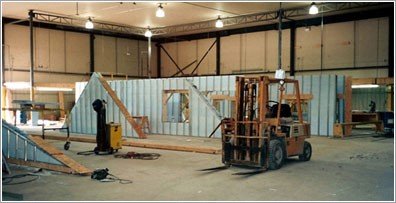

2. WALL ASSEMBLY

Walls are assembled at the factory based on the workshop plans determined at the previous step. Our installations are optimized and well equipped for the assembly and storage of the prefab walls. This step is done by a professional team well supervised and trained.

3.CONSTRUCTION SITE PREPARATION

The excavation and the footing are two major aspects of this step. The construction site also needs to be accessible to the different transporters involved in the following steps.

4. DELIVERY

5. INSTALLATION

6. FLOOR STRUCTURE AND ROOFING